Activated Carbon adsorption concentration + Catalytic Combustion (RCO)Activated carbon adsorption concentrated catalytic combustion (RCO) system is suitable for painting, printing, mechanical and electrical, home appliances, footwear, plastics and various chemical workshops volatile or leakage of harmful organic waste gas purification and odor elimination, the most suitable for low concentration, not suitable for direct combustion or catalytic combustion and adsorption recovery of organic waste gas treatment. Especially for the treatment of large air volume and low concentration, satisfactory economic and social benefits can be obtained.

Regenerative Oxidation System (RTO)

Regenerative Oxidation System (RTO)RTO is called Regenerative Thermal Oxidizer, so RTO is a mature and effective organic waste treatment device at present. Its principle is to oxidize the combustible waste gas into the corresponding oxygen and water at high temperatures, so as to purify the waste gas, and recover the heat released when the waste gas is decomposed, the waste gas decomposition efficiency reaches more than 99%, and the heat recovery efficiency reaches more than 95%. RTO equipment is composed of ceramic heat storage bed, automatic control valve, combustion chamber and control system.

Microbial waste gas treatment equipment

Microbial waste gas treatment equipmentMicrobial waste gas treatment equipment is a kind of equipment that can comprehensively treat organic waste gas through bacteria [biological fillers]. It is a equipment developed by our company with a large amount of funds and combined with years of production and design experience. It is a harmless organic waste gas treatment method.

Cyclone mixing spray tower

Cyclone mixing spray towerCyclone mixed spray tower is an important purification equipment in waste gas treatment, which is often used in industrial waste gas. It has remarkable effects on dust removal such as viscous dust, oily dust, fiber dust, grinding and polishing dust, and also has excellent effects on spray gas purification, industrial waste gas pretreatment, boiler desulfurization, oil smoke purification, etc.

Two-stage cyclone mixing spray tower

Two-stage cyclone mixed spray tower is an innovative and efficient dust removal equipment re-developed by our company based on the principle of cyclone mixed spray tower. By optimizing and innovating the cyclone mixed spray tower and making technical adjustments to the original structure, this bipolar cyclone spray has been developed with significantly improved planning efficiency, simple operation, convenient management and operation, and long life.

Square swirl spray tower

The square swirl spray tower is also called swirl plate spray tower. This equipment is a dust and waste gas treatment equipment developed by our company with strong technical capability and years of practical experience. For sticky dust, oily dust industrial waste gas pretreatment, fiber dust and other dry dust removal equipment can not deal with dust, waste gas can achieve a good treatment effect, the use of advanced paint mist separation technology, ingenious purification method, purification efficiency of more than 95%.

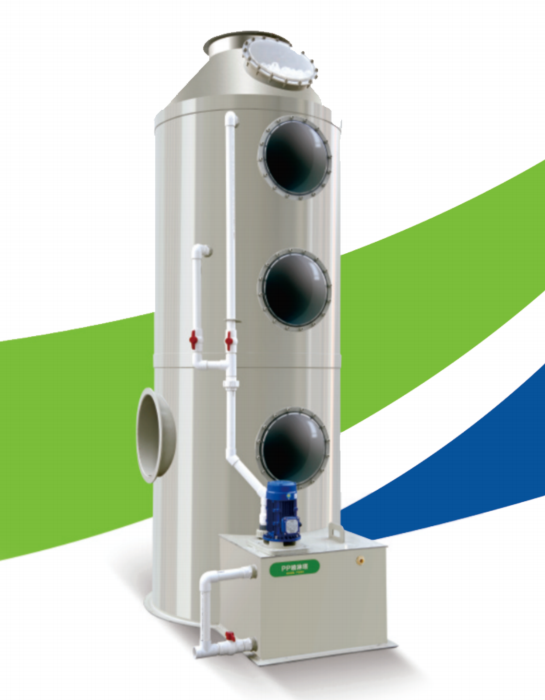

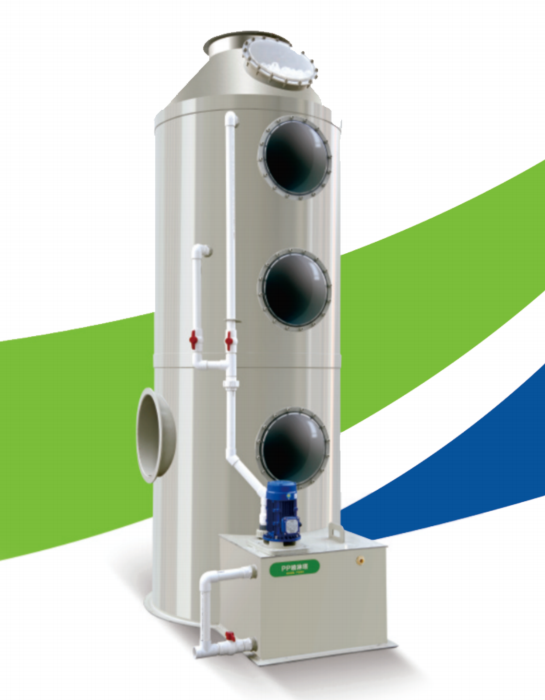

Round PP spray tower

Spray tower is an important purification equipment for waste gas treatment, which is often used in industrial waste gas treatment. According to the material can be divided into PP spray tower, stainless steel spray tower; There are round ones and square ones. The spray tower produced by our company has the advantages of high purification efficiency, compact structure, beautiful appearance, small footprint, etc., which can deal with acid fog waste gas, ammonia gas, hydrogen sulfide waste gas, VOC organic waste gas and so on.

UV photooxygen catalytic device

UV photooxygen catalytic device is the use of high-energy ultraviolet light to decompose and transform organic material principle to achieve the purpose of purification treatment. It is installed with high-energy UV lamps,UV lamps produce high-energy short-wave ultraviolet rays when working, so that organic pollutants in the exhaust gas decomposition, break the chain, such as: ammonia, trimethylamine, hydrogen sulfide, hydrogen methsulfide, methylmertan, dimethyl disulfide, carbon disulfide and styrene, triphenyl, benzol, toluene, xylene and other molecular chain structure, in a short time to be converted into low molecular harmless substances, so that the waste gas Purification, suitable for low concentration, large air volume of waste gas treatment.

Activated carbon exhaust gas adsorption device

Activated carbon is a black powder, granular or columnar amorphous porous carbon, the main composition of carbon, but also contains a small amount of oxygen, hydrogen, sulfur, nitrogen, chlorine, also has a fine structure like graphite, but the grain is small, layers of irregular accumulation. Has a large surface area (500-100mg), has a strong adsorption capacity, can adsorb gas on its surface, adsorption can be close to the quality of activated carbon itself.

Activated carbon is a very small carbon particle, has a large internal surface area, and there are smaller pores in the carbon particle - capillary, this capillary has a strong adsorption capacity, because the surface area of the carbon particle is very large, so it can fully contact with the gas, when these gases encounter the capillary tube is adsorbed, play a purification role. The essence of activated carbon adsorption is to use the characteristics of activated carbon adsorption to adsorb the organic solvent in the low concentration and large air volume waste gas to activated carbon.

UV photolysis activated carbon integrated machine

UV photolysis activated carbon integrated machine is a combination of UV photolysis purification and activated carbon adsorption two kinds of waste gas treatment technology - bulk waste gas treatment equipment, compared with the two separate equipment, purification efficiency is higher, the cost is reduced.

Low temperature plasma purifier

Low temperature plasma is an electrochemical process under the integrated action of electronics, chemistry, catalysis, etc., which relies on the powerful electric field ability generated by the plasma at an instant to ionize and split the chemical bond energy of harmful gases, thereby destroying the molecular structure of the exhaust gas and achieving the purpose of purification. Low temperature plasma purifier can effectively remove volatile organic matter, inorganic matter, hydrogen sulfide, ammonia, mercaptan and other major pollutants, as well as a variety of odor. Widely used in seafood and meat processing plants, food factory exhaust gas slaughterhouse exhaust gas, animal farm exhaust gas, zoo exhaust gas, etc. It can also be used in leather, shoe factories, furniture, glass and other factories that produce chemical odors, and can also be used in feed processing plants, tobacco production and processing, landfill, waste transfer, industrial and urban sewage treatment plants and other places with serious odors.

Industrial oil fume purifier

Industrial fume purification equipment is a kind of highly efficient and energy-saving fume purification equipment produced by our company based on many years of design and practical experience, and absorbed foreign advanced technology. The equipment has reasonable structure, small size, simple maintenance and low operating cost. By means of gas ionization and electric field force under high pressure, dust particles are separated from gas after being charged. Patented modular assembly technology, easy to choose, each module can handle 2000-4000 cubic meters/hour of air, low normal maintenance costs, long service life. The implementation of the "product humanization, standard globalization" quality concept, the use of high-low group modules, a number of innovative design, products are mainly for the demanding high-end oil fume purification market research and development, the use of Europe and the United States international two-stage electrostatic purification technology, ionization part of the cutting-edge discharge technology,8.0mm plate spacing so that its purification area than ordinary products up to 30% Guarantee 95% fume purification efficiency.